!!! USE CLONE in order to create a new country site !!! Don't translate this page!

Hydrogen hybrid power plant (MASTER)

ENERTRAG AG

The hybrid power plant pilot project in Prenzlau forms the highest point in the otherwise relatively flat countryside. This makes it a target for lightning. As the entire interior of the hall is classified as an Ex zone, conventional lightning protection would not suffice here.

The protection concept selected therefore comprises an isolated air-termination system erected at a distance from the structures and installations.

Pipeline exposed to AC voltage

Pipeline ENSO NETZ GmbH

The pipeline of ENSO NETZ GmbH is exposed to AC voltage caused by a railway line running parallel to it. This AC voltage must be limited to prevent AC corrosion and damage to the electronic devices caused by transient overvoltage.

The smart decoupling device VCSD discharges the temporary and long-duration AC voltage to a low-impedance earth. This also protects people from impermissibly high touch voltages.

Energy recovery plant

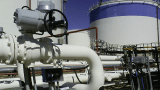

Energy recovery plant Taimeralm

Europe's most important oil pipeline uses an energy recovery plant which produces about 12% of the Austrian TAL pump stations' energy consumption.

The plant is extremely vulnerable to lightning strikes due to its location in the mountains, where the ground is stony and the soil resistivity poor. Therefore, a holistic view was taken of the lightning protection and the protection of the sensitive terminal devices.

The lightning protection concept comprises isolated external lightning protection using HVI technology, a closed meshed earthing system, meshed equipotential bonding and surge protection for the power supply, measuring, control and regulation (MSR) technology, and the telecontrol system.

Storage facilities for crude oil products

The CLH Group is a leading company on the Spanish market for the transportation and storage of crude oil products with a pipeline network of more than 4,000 kilometres and 38 storage facilities. CLH is mainly engaged in the receipt of crude oil products in the company’s facilities, their transportation and storage as well as delivery to final customers via tanker vehicles.

Permanent availability of the facilities is of utmost importance to ensure reliable fuel supply for petrol stations.

Due to the exposed location of these facilities, it is vital to install surge protective devices.

bayernets GmbH

bayernets GmbH in Munich transmits natural gas via a 1,412 km long high-pressure pipeline network in Bavaria. With a network area of 32,000 km2, the company is one of the largest network operators in Germany. As part of the gas network development plan, the MONACO natural gas pipeline will increase the security of supply in the south of Germany and Austria whilst also improving network stability and flexibility. The underground pipeline with a total length of about 87 km runs from the German-Austrian border in Burghausen to Finsing near Munich. There the natural gas is taken from the high-pressure network at the “Finsing 2” transfer station and fed into the downstream supply network at reduced pressure.

BAYERNOIL

The BAYERNOIL Raffineriegesellschaft mbH with sites in Neustadt and Vohburg is the biggest refinery in Southern Germany.

BAYERNOIL puts its trust in intelligent surge protection with space-saving DIN rail-mounted devices by DEHN. 600 BLITZDUCTOR XT arresters have been installed here.

The condition monitoring system continually controls the status of arresters in order to detect imminent overload as early as possible. The necessary service measures are taken in good time, in line with the high demands BAYERNOIL has on occupational, process and plant safety.

70 DRC MCM condition monitoring systems are in use here.

Open Grid Europe - Planning

Open Grid Europe GmbH (OGE) is Germany’s leading natural gas transmitter with a gas pipeline network of roughly 12,000 km. One of the most important hubs in the natural gas grid is the OGE compressor station in Werne: here 13 pipelines come together from different directions.

Open Grid Europe relies on DEHN’s 3D planning service to integrate the lightning protection concept in the complex architecture of the site (incl. ex areas!). This guarantees the efficient configuration of air-termination devices under consideration of all parts of the facility.

Open Grid Europe - Realisation

About a quarter of Germany’s natural gas consumption flows through the Werne compressor station. The expansion of the location as a central point in the gas supply grid is also part of the grid development plan.

The lightning protection concept with a highly efficient configuration of the air-termination devices and down conductors was successfully implemented in all areas (including ex areas) using certified system components by DEHN. The preparatory 3D planning and resulting detailed drawings made huge savings on installation resources, time and costs possible.

Gascade - North Stream Pipeline

As the operator, GASCADE Gastransport GmbH is responsible for the safe and reliable operation of the natural gas receiving station in Lubmin near Greifswald.

All possible risks were assessed and economically viable lightning and surge protection measures determined as part of a risk analysis in compliance with IEC 62305-2. Conducted interference impulse could be led in from the outside via the many interfaces and cause considerable damage to the PCS.

-

BAYERNOIL Raffineriegesellschaft mbH -

TAL - Transalpine Ölleitung GmbH -

GASCADE Gastransport GmbH -

German Cathodic Protection GmbH -

Linde AG Engineering Devision -

MERO Germany AG -

Open Grid Europe GmbH -

Steffel KKS GmbH -

TAL - Transalpine Ölleitung in Österreich Ges.m.b.H. -

bayernetz -

RMR -

ENSO NETZ GmbH

Partner to the oil and gas industry for more than 40 years.

These companies already trust in DEHN technology to make their plants and systems safer and more efficient.

Have you got questions? Contact us.

Team Process Technology

Telefon: +49 9181 906 1740